Lab0 is emerging from our two-year stealth mode with robotic solutions for logistics, focusing initially on fully automating inbound distribution center operations. Our solutions are capable of handling a wide variety of items and can adapt to the dynamic environments of busy distribution center facilities—and we couldn’t be more excited to announce our official launch.

Our mission is to simplify the user experience in logistics automation by addressing critical industry challenges like labor shortages, injuries, and operational inefficiencies with next-generation robotics enabled by AI-driven automation and technologies. Lab0 also simplifies install and integration efforts by providing complete autonomous logistics systems that automate entire workflows, thus giving customers a much higher value than “point solutions” that only solve part of a customer’s problems.

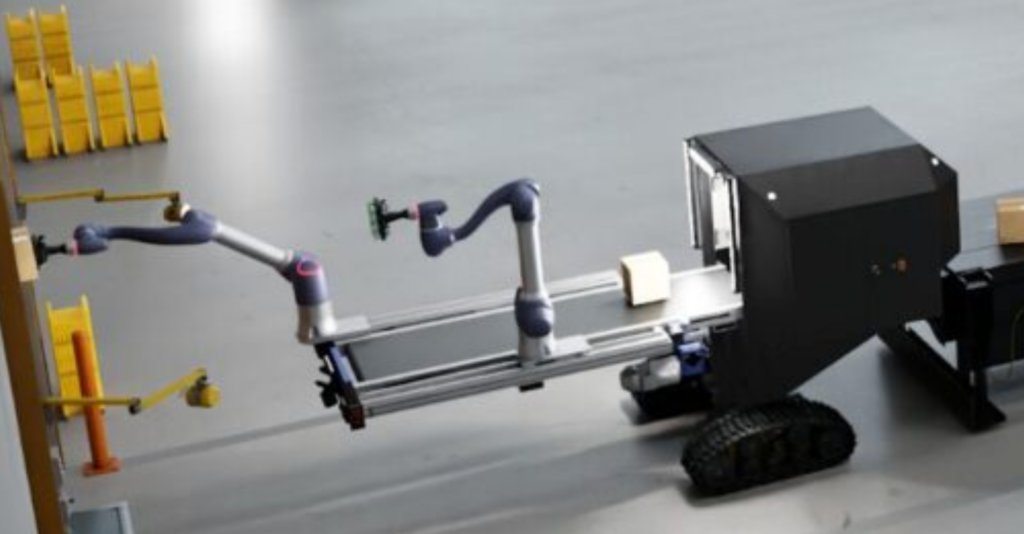

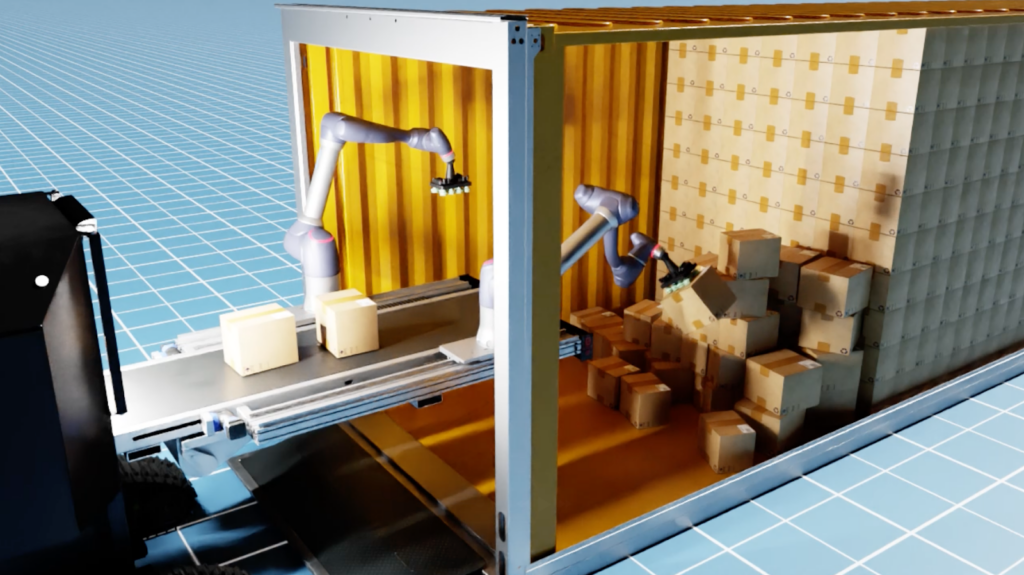

Our humanoid-inspired container unloading/loading robot, called Harvester, is part of our complete automated inbound system solution for distribution centers and warehouses (our RoboGlide system). Harvester is equipped with dual-arms and utilizes biomechanically-influenced, coordinated motion planning developed by our team of roboticists to accommodate the needs of our first customer: a major U.S. retailer with $30B in annual revenue and one of the nation’s top importers. Lab0’s combination of robotics expertise and real-world distribution center automation experience has resulted in the creation of an inbound automation system that is beyond anything available on the market today.

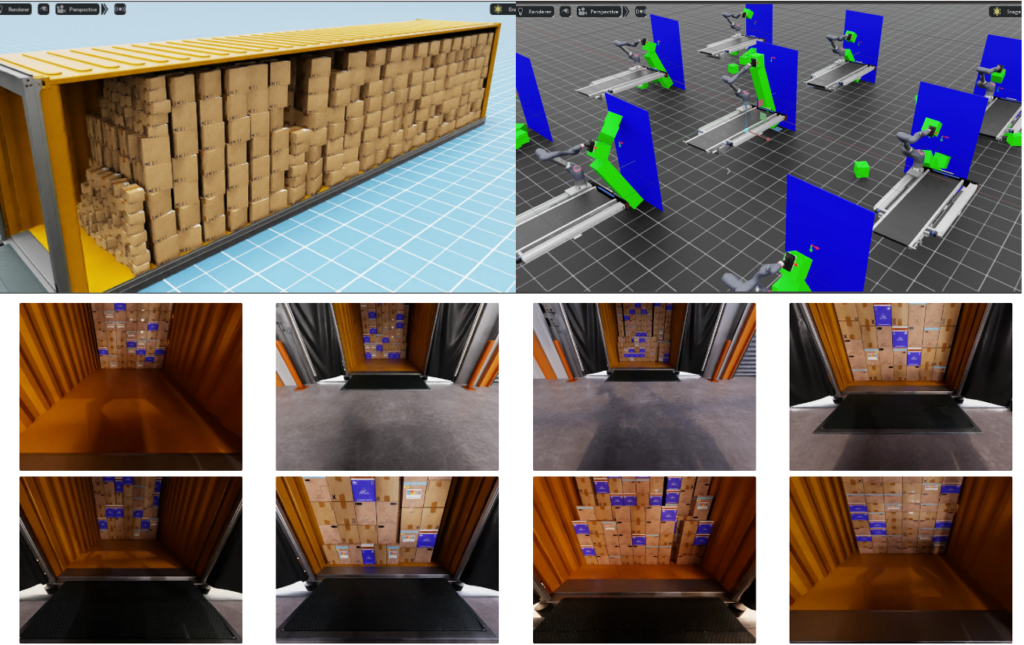

In order to be able to adapt to the dynamic nature of a distribution center and its high mix of products, Lab0 relies heavily on machine learning, using vast amounts of synthetic data generated by NVIDIA hardware and software. Prior to introducing our robots into the real-world, Lab0 simulates, tests and optimizes the operation of its robots in physically-accurate simulations by integrating NVIDIA Isaac Sim reference application for robot simulation and NVIDIA Isaac Lab framework for robot learning into its end-to-end development pipeline.

By fully embracing NVIDIA’s cutting-edge, simulation-first approach, Lab0 is able to more quickly set a new standard for efficiency, adaptability, and scalability in autonomous logistics.

From the outset, we knew that traditional automation solutions wouldn’t solve the persistent challenges in inbound logistics operations. Other existing solutions lack the compatibility and completeness to adapt to dynamic and unpredictable warehouse operations, often addressing only fragments of complex operational challenges. Lab0 takes a different approach, delivering comprehensive system solutions that solve complete logistics problems end-to-end.

Focused on transformative, foundational change, at Lab0 we have created our own proprietary robotics system inspired by human motion and perception and powered by NVIDIA’s advanced simulation capabilities and hardware. The result is a dual-arm robotics platform with sliding bases that adapts to unpredictable package configurations in shipping container environments, scales to meet unique operational demands, and—combined with the rest of the RoboGlide system—delivers high value in automating all inbound operations such as container unloading, product inspection and damage detection, sorting, and palletization.

The Power of Simulation-First Development

Before we build physical systems, we develop and test our solutions in a digital twin environment. Using NVIDIA Isaac Sim, a reference application for robot simulation built on NVIDIA Omniverse, we create physically accurate digital twins of real-world environments where we can test and perfect our systems. This approach has reduced both our development and deployment times significantly, allowing us to find mistakes, improve performance, and test design limitations, all before building anything in the physical world. NVIDIA physics engine’s stability and accuracy in Isaac Sim means we can trust the results of our virtual testing and reduce the amount of physical testing.

With such a high-fidelity virtual environment, we’re able to tackle complex challenges safely and with unprecedented speed. For example, we recently helped a major distributor reshape their workflow by identifying bottlenecks through simulation. Instead of disrupting their operations with trial-and-error testing, we arrived with a working solution in hand.

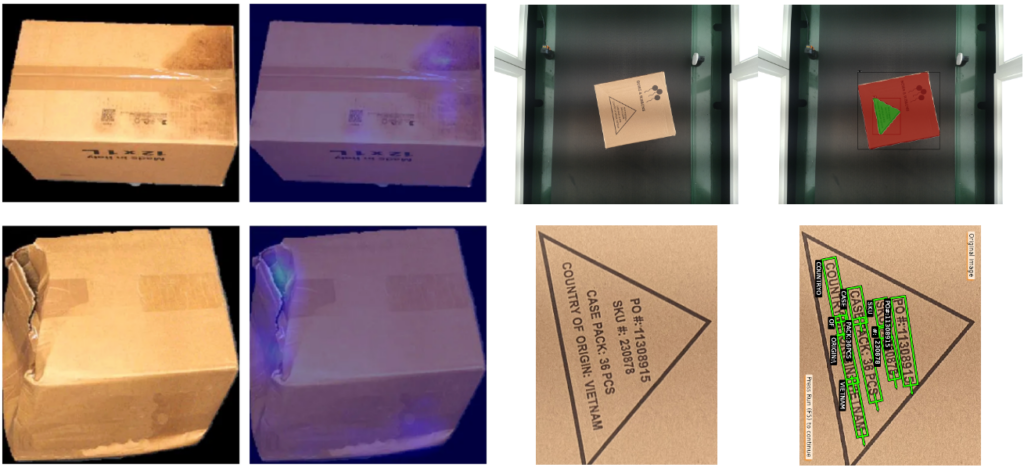

The flexibility of NVIDIA’s simulation frameworks allows us to customize solutions for diverse client needs, products, and spaces. Whether optimizing camera configurations for enhanced visual perception or testing end effectors for handling a variety of items with care and precision, Isaac Sim makes our workflow more efficient. Our advanced machine learning algorithms, developed and enhanced through Isaac Lab’s robot learning framework, are fully optimized for item identification, damage detection, and manipulation—enabling our proprietary systems to automatically adapt to and meet the unique challenges of individual warehouse environments.

By leveraging Isaac Lab, we’re advancing our warehouse logistics system through sophisticated AI and reinforcement learning. This integration enables intelligent decision-making and adaptive planning, creating a system that effectively manages the complex, dynamic challenges of modern logistics operations. Ultimately, such an innovative approach enhances our ability to accelerate the development lifecycle, improve accuracy, and establish a scalable, highly efficient logistics framework. The result is a system that handles intricate tasks with precision and reliability, driving superior operational performance.

Our simulation capabilities for our Harvester robot focus on four key areas:

- Vision Training Without the Wait: We generate synthetic data to thoroughly and rapidly train our computer vision systems, helping robots recognize objects accurately even under difficult conditions like dim lighting or partially hidden items.

- Smart Decision-Making: Our robots learn to make split-second decisions (and correct choices) through reinforcement learning—whether that’s finding the best way to unload a container or adapting when the environment suddenly changes—for example, when unstable packages suddenly fall during unloading. And when we encounter edge cases with real client containers, we can recreate that exact scenario in simulation, run thousands of tests, and validate solutions before implementing them in the real world.

- Physics-Based Learning: We teach our robotic systems to handle challenging items, including those involving soft body dynamics, as well as interacting with rigid bodies by simulating thousands of interactions in NVIDIA’s high-fidelity environments.

- Perfecting the Grip: Through reinforcement learning, our robots determine the optimal way to grasp different objects while accounting for their reach limitations and the object’s properties.

- Real-Time Planning: We enable our robotic systems to perform real-time planning and object manipulation in confined workspaces, incorporating advanced obstacle avoidance and navigation strategies. This includes tasks like precise object placement, dynamic re-planning, and safe navigation out of tight spaces, ensuring efficiency and adaptability in operationally constrained environments.

We enhance these capabilities using OpenUSD, an extensible open data interchange framework, and multicamera tools, which help us create exact virtual copies of customer scenarios from multiple data inputs. In fact, in a recent project, this cutting-edge tech helped us perfect our damage detection and categorization system, significantly improving both accuracy and operational speed.

And our simulation-first approach means we can rapidly scale our solutions across different warehouse environments and use cases. In short, we don’t need to reinvent the wheel to address the conditions at different warehouses. Instead, we can clone and adjust our existing virtual models to match each new space and use case, validate the changes through thousands of simulations, and deploy a fully trained and optimized robotic solution.

Humanoid-Inspired Design for Real-World Impact

Lab0’s Harvester robot is inspired by human biomechanics, so sophisticated real-time planning and object manipulation are baked into our machine-learning algorithms.

Our state-of-the-art dual-arm robotic system demonstrates advanced arm coordination that mirrors human movement patterns—particularly in confined spaces, where precise timing, fluid movements, and careful navigation are crucial. Because of their dynamic motion-planning capabilities, these systems optimize paths and trajectories in natural and efficient ways while ensuring collision avoidance. As a result, our system can handle complex tasks such as:

- Dynamic object manipulation with real-time adaptability

- Accurate picking of irregularly shaped and damaged products

- Autonomous recovery from anomaly conditions such as unstable boxes falling randomly

Lab0 believes in humanoid-inspired designs—and our humanoid-inspired Harvester robot is ready to provide real value in real, dynamic, industrial environments today.

Supply Chain Zero: The Vision for Tomorrow

Lab0’s commitment to “Supply Chain Zero”—eliminating inefficiencies and waste from logistics—is central to our mission (and our name). By integrating AI-driven automation with sustainable practices, we help clients:

- Achieve long-term cost savings

- Streamline operations to meet evolving demands

- Prevent worker injuries, and

- Reduce environmental impact

What Sets Lab0’s Robots Apart?

- System Solutions: Lab0 provides complete system solutions. Our inbound automation system, RoboGlide, provides container unloading/loading, product scanning, weighing, damage detection, sorting, palletization, and wrapping.

- Solving Real-World Needs: Lab0 developed RoboGlide to solve distribution problems faced by real-world customer needs, rather than designing a solution in isolation from actual customers.

- Dynamic Adaptability: Warehouses are constantly changing environments, and static systems can’t adapt. Lab0’s robots adjust in real time to incoming inventory, moving objects, and unexpected obstacles to ensure continuous, efficient operations. Lab0’s RoboGlide inbound automation system’s flexible and modular design allows customers to adapt and re-configure our system as they grow.

- Efficient and Accurate Path-Planning: Lab0’s robots optimize their trajectories, using proprietary motion planning algorithms, for speed and accuracy, reducing wear on machinery while maintaining peak efficiency and careful product handling.

Behind these capabilities is a robust utility patent that includes the entire inbound automated system, consisting of our Harvester humanoid-inspired robot, product scanning, weighing, and damage detection, and palletizing and wrapping. And this system seamlessly integrates with our advanced sorting algorithms, which leverage our high-precision scanning and weighing technology to enable real-time package assessment and intelligent routing decisions. Our sophisticated damage detection system uses multi-angle computer vision to identify even subtle signs of compromise, from minor dents to more serious damage.

Altogether, our extensive machine learning algorithms infuse our robotics with real-time decision-making, enabling our system to perform tasks and learn from them—and in this way, they become smarter and more efficient over time. Each scanned package, sorted item, and detected anomaly feeds into our learning pipeline, continuously refining our automation’s accuracy.

Lab0’s solutions are truly next-gen robotics for logistics, creating safer, more streamlined warehouses that can keep up with the demands of modern logistics.

What’s Next for Lab0

As we scale our solutions and partner with cutting-edge organizations like NVIDIA, we’re excited to keep showing how our robotics will drive meaningful change in the logistics industry. While our systems are already making an impact, we’re not stopping here. We’re focused on expanding our capabilities and further solidifying our position as a leader in warehouse and distribution center automation. We started with inbound operations automation—and that’s just the beginning.

Welcome to the future of autonomous logistics. Welcome to Lab0.

Meet us at NVIDIA GTC

As part of our official launch, we will showcase our innovations at NVIDIA GTC 2025, offering attendees a look at the technologies powering our groundbreaking solutions. Contact Carisa Platt at carisa.platt@lab0.com to schedule an appointment.